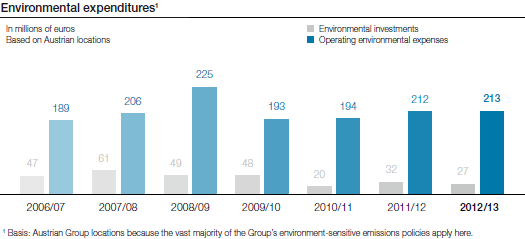

Environmental expenditures

In business year 2012/13, the environmental expenditures of the voestalpine Group1 equaled a total of EUR 240 million, thus remaining at the previous year’s high level (EUR 244 million). Specifically, approximately EUR 27 million were attributed to environmental investments (2011/12: EUR 32 million) and EUR 213 million (2011/12: EUR 212 million) went to ongoing operating expenses for environmental systems.

Focus of environmental measures

The focus of the activities, which partly have already been presented in detail in previous letters to shareholders, was also placed on the areas of energy and raw materials efficiency, air and water pollution control as well as waste prevention and recycling.

For example, at the Linz site, an additional melting pot gas holder was put into operation so that the plant can optimize its use of the melting pot gas accumulated during the LD-process in the steel mill and minimize any losses through flaring. In addition, in the area of air purification, the first DeNOX system ever installed in Europe for the denitrification of sinter exhaust was put into operation at the end of 2012. This trend-setting system will enable a further reduction of NOx emissions by approximately 400 tons per year.

Furthermore, the environmental remediation of the coking plant at the Linz site, which began in October 2012, represents a long-term remediation focal point. Restoration of the subsoil, which became heavily contaminated due to the destruction in the Second World War, will take place in gradual stages and, due to the dimension of the affected area, will last for a period of at least ten years.

To increase energy efficiency in the Special Steel Division, the Group collected data on current conditions at eight production sites; in addition, it defined energy KPIs (Key Performance Indicators). The implementation of concrete measures should lead to a sustained increase in energy efficiency, and thus an annual savings of a magnitude ranging up to EUR 4 million. Those projects already realized primarily relate to the improved heat insulation of buildings, multiple process optimizations, and a change in combustion fuels from oil to liquid natural gas at the site in Hagfors, Sweden.

The environmental plans at a number of the Metal Engineering Division’s Austrian and international sites were specifically geared toward the further optimization of water resources management and energy efficiency across all process steps (including additional heat insulation and heat recovery measures). The same approach applies to the Metal Forming Division, which additionally invested in a number of companies in order to lower production waste first and foremost, and to improve its re-use as valuable raw materials. This was able to substantially improve resource efficiency in production.

For several years now, the ambitious environmental efforts of the voestalpine Group have been honored with national and international distinctions. Thus in June 2012, voestalpine Schienen GmbH was given the EMAS Award for the “Best Austrian Environmental Team” in recognition of the unique commitment demonstrated by the employees and management staff in minimizing the environmental impact of business operations.

Environmental policy topics

EU 2050 Roadmaps

In 2011, the EU Commission published a series of announcements in the form of so-called “2050 Roadmaps” on the issues of climate policy, energy, and resource efficiency and, with the same time horizon, a white book on the issue of traffic and transportation as well. Meanwhile, the Commission’s Roadmaps were also discussed both by the European Parliament as well as the Council of the European Union. Whereas the EU Parliament was able to agree on a resolution about all four announcements, the Council was only able to achieve consensus on the resource efficiency roadmap. Thus, the Commission has been given an unequivocal implementation assignment in this area only; in other words, the Commission’s implementation activities are currently restricted to the area of resource efficiency.

In the area of climate policy, the EU Commission is pushing ahead with the further advancement of the Emissions Trading Directive. For example, it has made recommendations on the changes to the auction calendar (“backloading”) to increase certificate prices by means of interventionist measures. In order to continue making progress on the strategic development of climate policy, despite the absence of the European Council’s complete assignment, in March 2013 the Commission launched a public survey about climate policy leading up to 2030.

CO2 emissions trading

The draft of the allocation table that applies to Austria was already published nationally on March 5, 2012, and presented to the EU Commission. However, other member states did not transmit their records until much later; consequently, the review of these proposals is currently still pending. Since the EU Commission can only determine the Cross-Sectoral Correction Factor—which is used to balance the allocations using the EU-wide cap—after all reviews have been completed, the country-specific allocations can only be finalized once the review of all data has been concluded. Hence, at this time it is impossible to make any reliable assertions on the definitive CO2 cost burden for the next few years.

The compilation of a “Low Carbon Steel Roadmap” by EUROFER, the European Steel Association, currently represents an important focus in this context. It contains more definitive statements on the EU roadmaps and on the technically feasible potential for the European steel industry to reduce CO2 emissions as well as on the cost-effectiveness of such reductions. Potential is characterized specifically by the optimized use of available quantities of scrap, by the ongoing technological developments of the systems, and—though only on a long-term basis—by so-called “break-through” technologies, such as the partial replacement of the conventional blast furnace route through DRI/EAF steel production, or in other words, through the direct reduction of iron ore and its further processing on the basis of electric furnaces.

Life Cycle Assessment

Life Cycle Assessment (LCA) is a systematic analysis of the environmental impact of products across their entire life cycle. Moreover, it is also becoming increasingly significant on the customer side. A Group-wide working group was established on this issue within voestalpine (incorporating Purchasing, Sales, Marketing, Production, and Research as well as the environmental sector). In addition to monitoring developments, this working group handles the coordination of various LCA activities, such as data management and active participation in interest groups that represent the industry, for example, EUROFER and the World Steel Association.

Industrial Emissions Directive

The revised version of the Industrial Emissions Directive (IED) 2010/75/EU became effective at the start of 2011, replacing the IPPC Guideline (Integrated Pollution Prevention and Control Directive). It is intended to guarantee the Europe-wide standardization of systems-oriented threshold values and measures for certain industry facilities. On a national level, it is currently being implemented through the relevant administrative laws for facilities requiring permits (Materienrechte), such as the Waste Management Act, the Industrial Code, and Water Rights Act.

Currently at the voestalpine Group, the relevant plants and facilities are being inspected with an eye to any adjustment needs so that the Group can plan for and implement the measures and changes necessitated by these European regulations in a timely manner. To ensure the ecologically efficient implementation of the provisions of the industrial emissions directive on a national level, the Group is also actively involved with the ongoing implementation process within Austria.

1 Basis: Austrian Group locations because the vast majority of the Group’s environment-sensitive emissions policies apply here.